Gửi email cho chúng tôi

Các ứng dụng của các công cụ kim cương là gì?

Nowadays, diamond tools are widely used. Diamond tools have the characteristics of high hardness, high compressive strength, good thermal conductivity, wear resistance, corrosion resistance, long life, etc. They are suitable for processing non-ferrous metals and non-metallic materials, and have high processing accuracy and processing efficiency in high-speed cutting. So what are the applications of diamond tools? The following editor of Zhongyeda will introduce it to you.

Application of diamond tools:

1. Processing difficult-to-process non-ferrous metals

When processing non-ferrous metals such as copper, zinc, aluminum and their alloys, these materials adhere to the tools and are not suitable for processing. Diamond tools made of diamond with low friction coefficient and low affinity with non-ferrous metals can prevent metal and tools from sticking together. Due to the large elastic modulus of diamond, the deformation of the blade is small during cutting, and the extrusion deformation of the non-ferrous metal being cut is small, so that the cutting process is completed under small deformation, which can improve the surface quality of cutting.

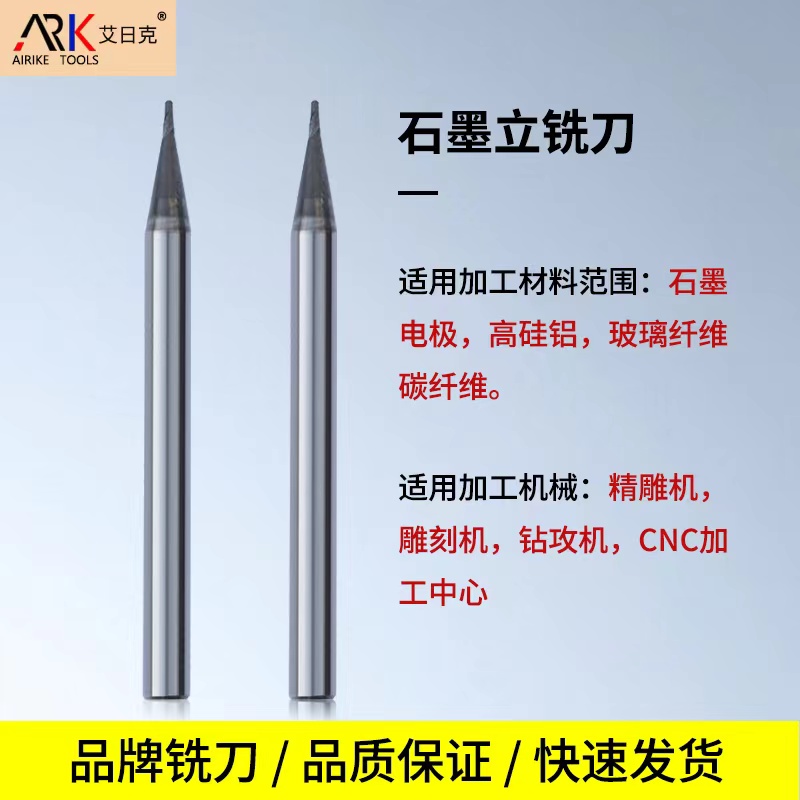

2. Processing of difficult-to-process non-metallic materials

When processing difficult-to-process non-metallic materials containing a large number of high-hardness particles, such as glass fiber reinforced plastics, silicon-filled materials, and hard carbon fiber/epoxy resin composites, the hard particles of the material cause serious wear of the tool, and it is difficult to process with carbide tools. Diamond tools have high hardness and good wear resistance, so the processing efficiency is high.

3. Ultra-precision processing

With the advent of modern integrated technology, machining is developing in the direction of high precision, which puts forward very high requirements on tool performance. Because diamond has a small friction coefficient, low thermal expansion coefficient, and high thermal conductivity, it can cut extremely thin chips, and the chips are easy to flow out. It has low affinity with other substances and is not easy to produce built-up edge. It has low heat generation and high thermal conductivity, which can avoid the influence of heat on the blade and workpiece. Therefore, the blade is not easy to be blunted, the cutting deformation is small, and a higher quality surface can be obtained.

The above application of diamond tools is shared here for everyone. I hope this article will be helpful to everyone. If you have other questions about diamond milling cutters that you want to know, you can follow Zhongyeda or leave a message to the editor. We look forward to discussing with you!

- Cái nào tốt hơn, dao phay than chì hay dao phay HSS?

- Bạn có biết những cách thiết thực để giảm chi phí xử lý dao phay acrylic là gì không?

- Điều gì làm cho dao phay khắc đá trở thành tương lai của chế biến đá chính xác?

- Tốc độ quay và tốc độ nạp của dao phay hàn là bao nhiêu?

- Làm cách nào để căn chỉnh máy cắt rãnh chữ T?

- Dao phay kim cương là gì và nó nâng cao hiệu quả gia công như thế nào?

Liên hệ chúng tôi

Khu công nghiệp Paibang, thị trấn Henggang, quận Longgang, Thâm Quyến

Bản quyền © 2025 Thâm Quyến Zhongyeda Precision Technology Co., Ltd. Tất cả quyền được bảo lưu.